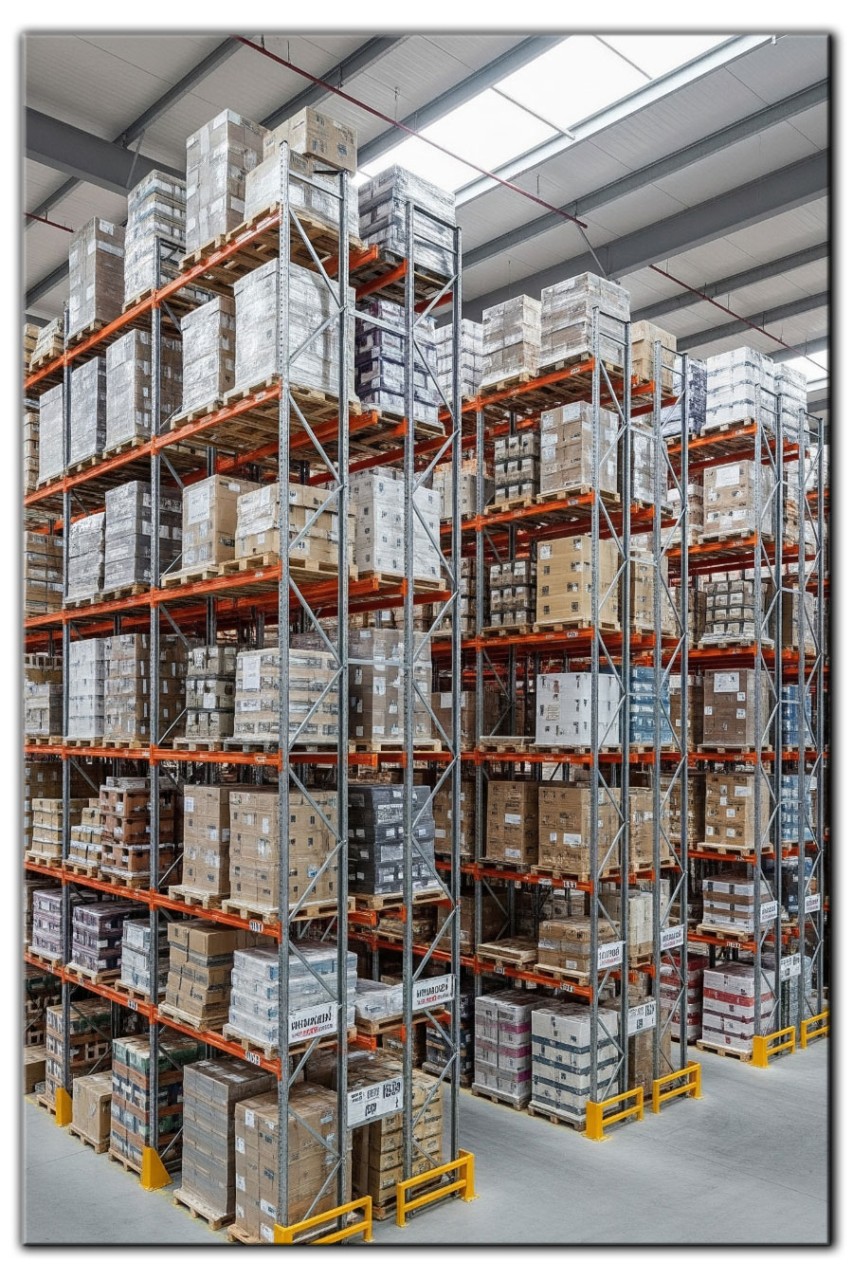

Enhancing Warehouse Efficiency: The Role of Industrial Racking Systems

Understanding Industrial Racking Systems

Industrial racking systems refer to a variety of shelving and storage solutions designed to accommodate different types of goods and inventory. From pallet racks and cantilever racks to shelving and mobile racks, these systems are engineered to maximize vertical space, streamline operations, and enhance inventory management.

Types of Industrial Racking Systems

- Selective Racking: This is the most common type of racking used in warehouses. Selective racking allows easy access to each pallet, making it ideal for businesses that require quick retrieval of goods. It accommodates various pallet sizes and weights, offering flexibility in storage.

- Drive-In/Drive-Through Racking: These systems are designed for high-density storage. They allow forklifts to drive into the racking structure to load or unload pallets. This method significantly increases storage capacity but is best suited for products with a limited variety and high turnover.

- Push Back Racking: This dynamic storage system allows pallets to be stored at an incline. When a pallet is removed, the remaining pallets roll forward, making it easy to access items. This type of racking is ideal for first-in, first-out inventory management in businesses with perishable goods.

- Cantilever Racking: Perfect for storing long or bulky items, cantilever racking consists of horizontal arms extending from posts. This system allows for easy loading and unloading of oversized items, such as lumber or pipes.

Benefits of Implementing Industrial Racking Systems

- Maximized Space Utilization: Industrial racking systems optimize vertical space, enabling warehouses to take advantage of the full height of the building. This is especially crucial in urban areas where every square foot can be costly.

- Increased Productivity: Efficient racking facilitates smoother workflows. Workers spend less time searching for items and can quickly access the stored products, leading to reduced order fulfilment times. Well-organized inventory also reduces the likelihood of errors.

- Improved Inventory Management: Modern racking systems often incorporate technology such as barcode scanning and inventory management software. This integration helps businesses track inventory levels, monitor stock movement, and minimize the risk of overstocking or stockouts.

- Enhanced Safety: Properly designed and installed racking systems promote a safer work environment. Racking systems can be engineered to meet safety regulations, reducing the risk of accidents and injuries caused by overloaded or unstable shelves.

- Cost Efficiency: By maximizing warehouse efficiency through effective racking solutions, businesses can potentially lower overall operating costs. Improved productivity and safer environments can lead to reduced labor costs, fewer insurance claims, and enhanced employee satisfaction.

Selecting the Right Racking System

Choosing the right industrial racking system requires an understanding of your specific warehouse operations and inventory needs. Here are some key considerations:

- Inventory Size and Weight: Understanding the dimensions and weight distribution of your products is crucial to selecting a racking system that will sustain your operations.

- Inventory Turnover: Is your inventory fast-moving or slow-moving? The type of racking system you choose can differ significantly depending on the turnover rate of the products stored.

- Space Constraints: Assess the size and layout of your warehouse. A well-designed storage solution will optimize your layout while allowing for smooth operations.

- Future Growth: Consider your business's growth plans. Choose a racking system that can be easily expanded or reconfigured to accommodate changes in inventory or space.

For more information and guidance regarding improving your warehouse efficiency, contact Murriers today.

Comments