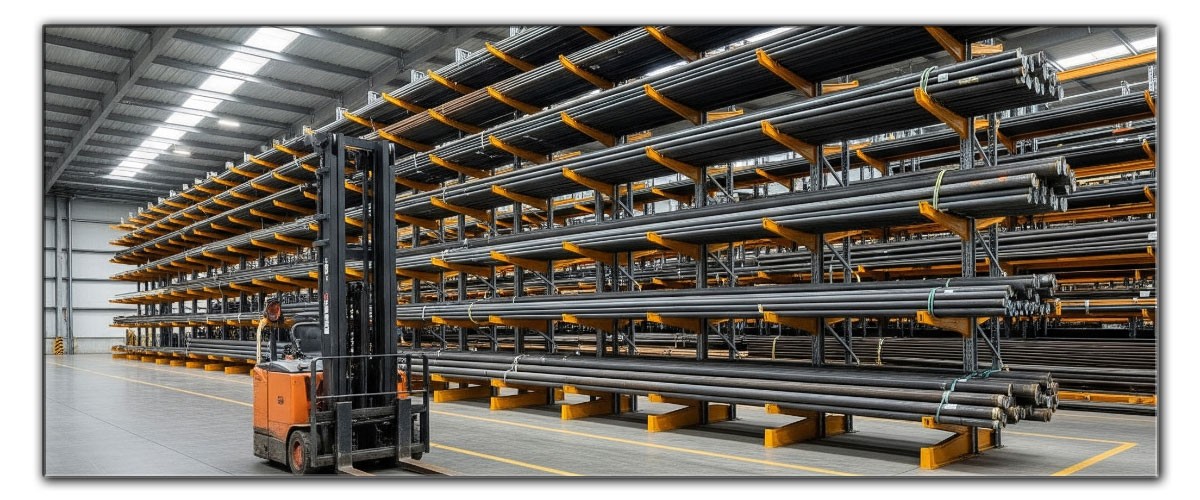

6 Reasons Why Cantilever Racking is Perfect for Heavy-Duty Storage

In the world of industrial storage solutions, maximizing space while ensuring safety and accessibility is crucial. Among the various options available, cantilever racking stands out as an exceptional choice for heavy-duty storage needs. Whether you're managing a warehouse, a distribution centre, or any facility that handles bulky items, the benefits of cantilever racking can help streamline your operations. Here are six compelling reasons why cantilever racking is ideal for heavy-duty storage

1. Designed for Bulky and Odd-Shaped Material

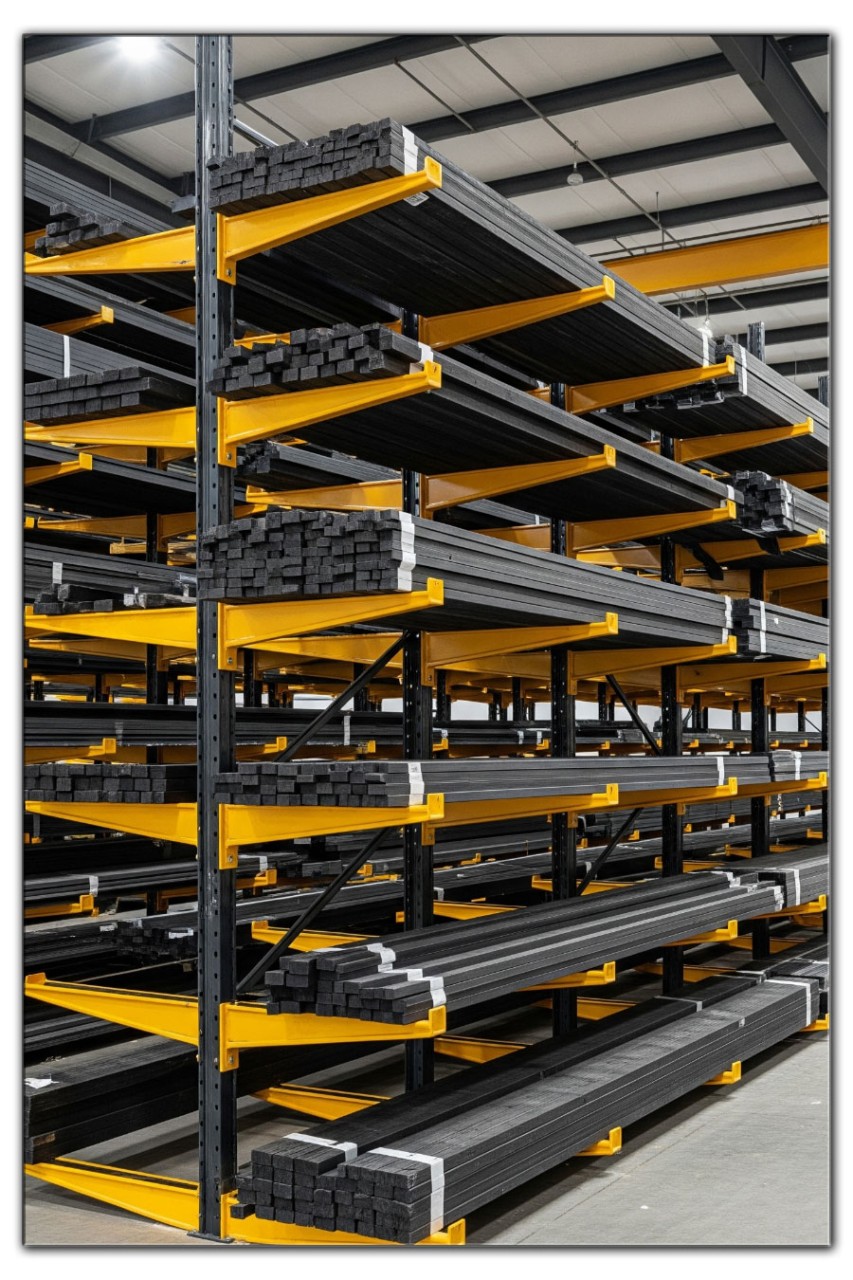

Cantilever racking is specifically engineered to handle items that are long, heavy, and irregularly shaped. Featuring arms that extend horizontally from a vertical post, this type of racking allows you to store products like lumber, pipes, sheets of metal, or large machinery parts without worrying about the constraints typical of traditional shelving. This flexibility makes cantilever racking an optimal choice for industries such as manufacturing, construction, and retail.

2. Maximized Vertical Storage Capacity

One of the key advantages of cantilever racking is its ability to utilize vertical space efficiently. The open design of the racking system allows for stacking materials upwards without obstruction from shelves or beams. This vertical optimization can significantly increase your storage capacity, helping you make the most out of your facility's footprint, particularly in areas with high ceilings.

3. Easy Accessibility and Organization

Cantilever racking ensures easy access to all stored items, as it eliminates the need for front-to-back storage. With items stored on accessible arms, employees can quickly retrieve what they need without having to navigate cumbersome shelving systems. This level of accessibility also promotes better organization, allowing you to categorize and segregate stock easily while reducing the risk of damage during handling.

4. Sturdy Construction for Heavy Loads

When it comes to heavy-duty storage, durability and strength are paramount. Cantilever racks are typically constructed from robust materials, such as steel, which are capable of supporting significant weight. This sturdiness means you can confidently store heavier items without the fear of rack collapse or damage to stored goods. Additionally, many cantilever racking systems are adjustable, allowing you to customize arm heights to accommodate different materials efficiently.

5. Flexible Configuration Options

Every warehouse has unique storage needs, which is why the flexibility of cantilever racking is a major advantage. These systems can be configured to suit the specific requirements of your inventory, including height, width, and depth adjustments. Furthermore, cantilever racks can be easily expanded or reconfigured as your business needs evolve, making them a long-term storage solution that grows with you.

6. Cost-Effective Storage Solution

While the initial investment in cantilever racking may be higher than other options, the long-term savings can be significant. Their durability leads to lower maintenance costs, while improved workflow efficiency means less time is spent retrieving and managing inventory. Additionally, the maximization of storage space can lead to reduced rental costs if your warehouse is limited in size. Overall, cantilever racks represent a smart, cost-effective investment for any business prioritizing heavy-duty storage.

For businesses dealing with heavy and irregularly shaped materials, cantilever racking offers a robust, flexible, and efficient storage solution. Its superior design maximizes vertical space, enhances accessibility, and ensures the safety of your products. If you're looking to optimize your warehouse or storage facility, consider integrating cantilever racking into your operations.

Comments