7 Essential Tips for Successful Cantilever Racking

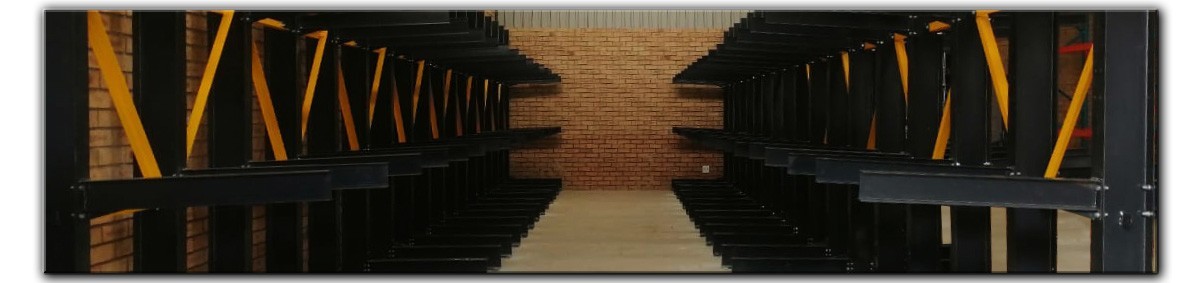

If you're in the business of storing long or bulky items, you might have encountered cantilever racking systems. These versatile solutions are designed to maximize vertical space and organize inventory efficiently. Whether you're handling lumber, pipes, or furniture, cantilever racking can be a game-changer for your warehouse operations. To help you optimize your storage strategy, here are seven essential tips for successful cantilever racking.

1. Choose the Right System

Before diving into cantilever racking, assess your specific storage needs. Consider the variations in weight, size, and type of items you plan to store. Different cantilever racking systems accommodate various capacities and configurations, ranging from light-duty for smaller items to heavy-duty systems for larger loads. Murriers offers a range of options that can be tailored to your needs.

2. Maximize Vertical Space

3. Implement Proper Load Distribution

Proper weight distribution is crucial for maintaining the integrity of your cantilever rack. Heavy items should be placed lower on the rack for stability, while lighter items can be stored higher. This not only prevents accidents but also extends the lifespan of your racking system. Always adhere to load capacity guidelines provided by the manufacturer.

4. Maintain Accessibility

While maximizing your space is essential, accessibility should never be overlooked. Ensure that your cantilever racking setup allows for easy access to all items without extensive climbing or reaching. Clear pathways should be maintained for forklifts and personnel. Regularly review and reorganize inventory to keep frequently accessed items within easy reach.

5. Invest in Safety Features

Safety should always be a top priority in any storage facility. Invest in safety features such as safety bars, railings, and protectors to reduce the risk of accidents. Additionally, train staff on safe loading and unloading practices to minimize the potential for injuries or damage to the inventory.

6. Regularly Inspect Your System

Regular inspections of your cantilever racking system are crucial for ensuring its functionality and safety. Look for signs of wear and tear, such as bent arms or structural damage. Establish a routine inspection schedule to identify issues early and address them before they become more significant problems.

7. Optimize Inventory Management

Finally, consider implementing an inventory management system that works alongside your cantilever racking. Track the quantities and locations of your stock electronically for quick access and better planning. Efficient inventory management helps ensure that your storage space is used wisely and can streamline the picking processes for orders.

If you're looking to make the most out of your space with a tailored cantilever racking system, contact Murriers today. Our experts can help you design a solution that optimizes your warehouse operations and ensures a safer and more efficient storage environment. Let us help you transform your space!

Comments