Don't Move, Improve: How Turnkey Mezzanine Flooring Unlocks Your Warehouse's Hidden Potential

The walls are closing in. You can feel it every time you walk the floor. Aisles are tighter, pallets are staged in every available nook, and the phrase "we're at capacity" has become a daily mantra. For any successful warehouse professional, this is a familiar, if stressful, sign of growth.

The conventional wisdom presents you with a daunting choice: either begin the monumental, costly, and disruptive process of relocating to a larger facility, or stifle your growth and turn away business.

But what if there was a third option? An option that doesn't involve months of downtime, astronomical moving costs, or the logistical nightmare of uprooting your entire operation. What if you could double your usable floor space right where you are, with minimal interruption to your daily workflow?

This isn't a futuristic concept; it's a strategic reality made possible by turnkey mezzanine flooring solutions. It's time to stop looking outward for more square footage and start looking upward.

The True, Hidden Costs of Relocation

Before we explore the power of vertical expansion, it's crucial to understand the full picture of what a facility move entails. It's far more than just signing a new lease and hiring a moving truck. The true cost of relocation is a drain on your most valuable resources: time, money, and operational momentum.

- Crippling Downtime: This is the number one killer. Every hour your operation is offline packing, moving, and unpacking is an hour you aren't receiving goods, picking orders, or shipping to customers. The loss of revenue and the potential damage to your reputation for reliability can be catastrophic.

- Exorbitant Financial Outlay: Consider the direct costs: real estate broker fees, lawyers, hefty security deposits, higher lease payments, and the physical moving expenses. Then add the indirect costs: new IT infrastructure, potential facility fit-out costs, and updating all company addresses and marketing materials. The final bill is often staggering.

- Logistical Chaos: Orchestrating a move is a full-time job in itself. It involves coordinating with landlords, movers, IT specialists, and equipment installers, all while trying to manage your core business. Inventory transfers alone are a high-risk process, ripe for product damage or loss.

- The Human Element: A new location can mean a longer, more difficult commute for your most valuable asset—your skilled and experienced team. You risk losing trusted employees, leading to the high costs and operational drag of recruitment and training.

When you weigh these factors, relocating starts to look less like a solution and more like a massive, high-risk gamble.

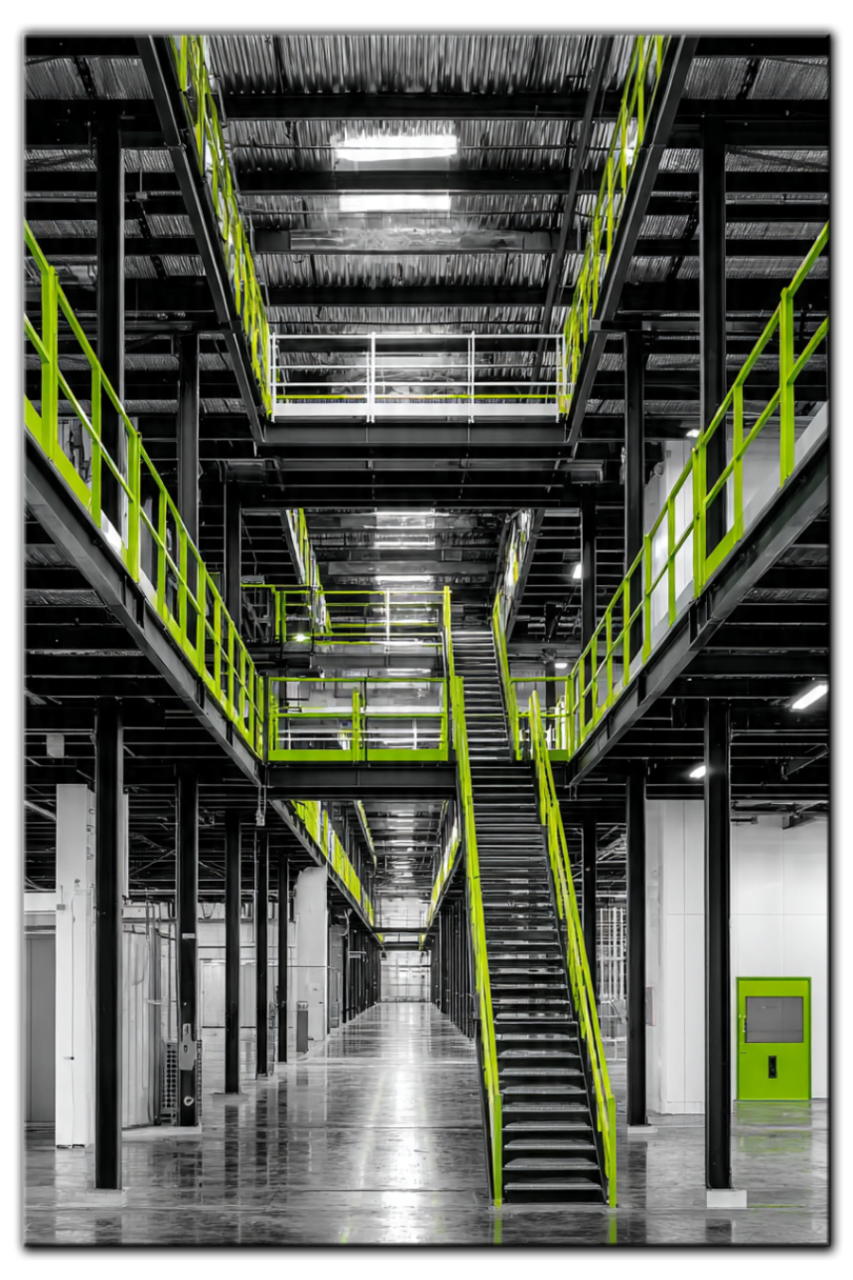

The Vertical Revolution: What is a Mezzanine Floor?

A mezzanine is an intermediate floor built between the main floors of a building, effectively creating a new level of usable space within your existing footprint. Constructed from high-strength steel, these structures are not just simple platforms; they are robust, custom-engineered extensions of your facility.Think of it as a space multiplier. That unused vertical air above your racking and operational areas? That's your hidden asset. A mezzanine flooring installation transforms that empty void into a productive, revenue-generating space. This new level can be used for:

- Additional Storage: Incorporate more shelving and racking systems to maximize storage space.

- Office Space: Build out administrative offices, break rooms, or meeting areas directly above the warehouse floor.

- Light Assembly & Packing Stations: Create dedicated zones for value-added services without sacrificing floor-level storage.

- Observation Decks: Allow for better management oversight of floor operations.

The Game-Changer: Demystifying the "Turnkey Mezzanine" Process

The word "turnkey" is often used in business, but in the context of a warehouse expansion, it carries immense weight. A turnkey mezzanine solution means you partner with a single, expert company that manages every single aspect of the project, from the first sketch to the final safety inspection.

You don't have to juggle architects, engineers, fabricators, and multiple installation crews. You get one point of contact, one streamlined plan, and one team accountable for delivering a seamless result. This is how we transform a complex construction project into a manageable, predictable process that respects your ongoing operations.

Here's a look at our comprehensive turnkey process:

Step 1: Consultation & Site Survey It all starts with listening. Our experts come to your facility to understand your pain points, your growth objectives, and your specific workflow. We take precise measurements and assess everything from capacity to ceiling height and column placement.

Step 2: Custom Design & Engineering This is where your vision takes shape. Our team designs a mezzanine that is perfectly tailored to your needs. We focus on optimizing column spans for minimal interference, calculating precise load-bearing requirements for your intended use, and ensuring the design integrates perfectly with your existing layout, including fire escapes, conveyor systems, and workflow patterns.

Step 3: In-House Steel Manufacturing Because we manufacture our own steel components, we have unparalleled control over quality, timelines, and cost. Every beam and column is fabricated to exacting standards in our own facility, ensuring a perfect fit and uncompromising structural integrity.

Step 4: Dedicated Project Management You will be assigned a dedicated project manager who becomes your single point of contact. They handle all scheduling, logistics, and coordination, providing you with regular updates and ensuring the project stays on track and on budget. No more chasing down different contractors for answers.

Step 5: Phased, Minimal-Disruption Installation This is the cornerstone of the turnkey promise. We understand that you can't afford to shut down. Our installation teams are experts in working within active warehouse environments. We work with you to create a phased installation plan, often working during off-hours or sectioning off small, manageable areas at a time to keep your core operations flowing smoothly. Our goal is for you to barely notice we're there—until you see your new space ready for use.

Step 6: Full Systems Integration A mezzanine is just the beginning. As a full-service warehousing solutions provider, we integrate the entire system. This includes the seamless installation of industrial shelving, pallet racking, safety gates, staircases, and any other equipment needed to make the new space fully functional from day one.

Step 7: Final Inspection & Handover Once the installation is complete, we conduct a rigorous final inspection with you to ensure every detail meets your satisfaction and all safety standards. Only then do we hand over the keys to your newly expanded, optimized operational space.The Unbeatable Advantages of a Turnkey Approach

By choosing a turnkey mezzanine solution, you are not just buying a product; you are investing in a strategic advantage.

- Speed & Efficiency: A single, coordinated team eliminates the delays and miscommunications that plague projects with multiple contractors. Your expansion is completed in a fraction of the time it would take to relocate.

- Cost-Effectiveness & ROI: A mezzanine typically costs significantly less than relocating or building an extension. You leverage an asset you already own (your building's height), leading to a much faster and more impressive return on investment.

- Operational Continuity: This cannot be overstated. Our minimally disruptive process protects your revenue streams, keeps your team productive, and maintains your customers' trust throughout the project.

- Guaranteed Quality & Safety: With one company overseeing design, manufacturing, and installation, there is end-to-end accountability. You receive a structurally sound and safe solution built to last.

- Future-Proof Scalability: A steel mezzanine is a modular asset. As your needs evolve, it can often be modified, expanded, or even relocated, providing a level of flexibility a traditional building expansion cannot offer.

Is It Time for You to Look Up?

Ask yourself these questions:

- Are you constantly battling for floor space but have high ceilings?

- Is the thought of operational downtime during a facility move keeping you up at night?

- Do you need to add office, assembly, or specialized storage areas without sacrificing your current footprint?

- Are you looking for a strategic, long-term solution to support your company's growth, not just a temporary fix?

Comments