What is Cantilever Racking and How is it Used in a Warehouse Environment?

In today's fast-paced and ever-evolving logistic industry, efficient use of warehouse space is paramount for maintaining productivity and ensuring smooth operations. One solution that has gained significant traction in warehouses is cantilever racking. This innovative storage system is designed to help businesses maximize vertical space while keeping their operations organized and accessible. In this blog post, we'll explore what cantilever racking is, its benefits, and how it's commonly used in warehouse environments.

Understanding Cantilever Racking

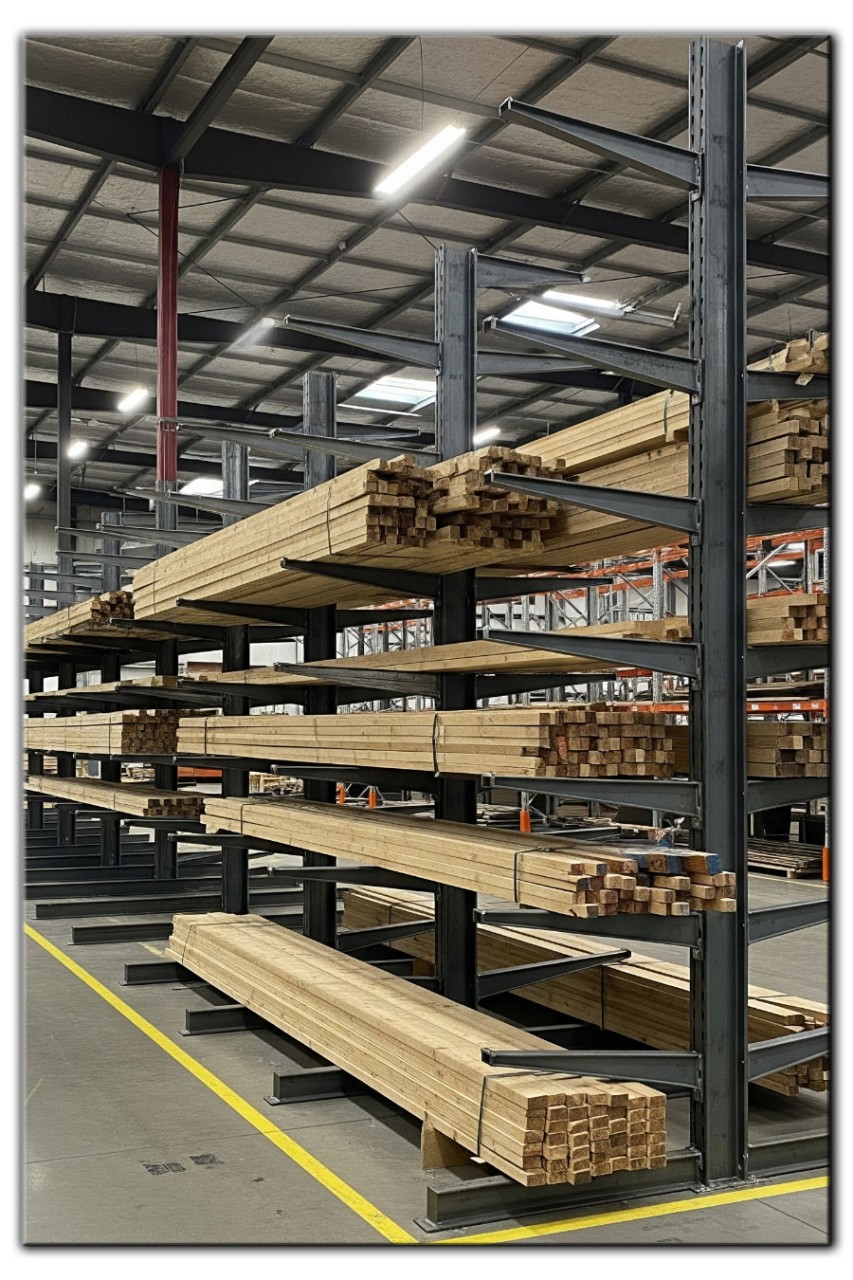

Cantilever racking is a type of storage solution that features arms extending from a central vertical beam, allowing items to be stored on either side. Unlike traditional pallet racks, cantilever racking is specifically engineered to handle long, bulky, or irregularly shaped items. The design allows for flexibility, making it an ideal choice for businesses that need to store a variety of products, such as lumber, pipes, furniture, and other long or heavy items. The structure can often be customized in terms of height, width, and load capacity to suit specific needs.

Structure and Design

The key components of a cantilever racking system include:

- Vertical Columns: These vertical supports provide the primary strength of the racking system and are anchored to the floor.

- Arms: The horizontal extensions from the vertical columns that hold items. Arms can be adjustable, allowing users to change the height between racks based on the size of the products being stored.

- Base Plates: These are anchored to the ground to ensure stability and can be designed with additional safety features.

- Cross Bracing: This structure adds stability and prevents swaying or movement that could potentially lead to accidents.

Overall, the modular design of cantilever racks allows for scalability, enabling warehouses to expand their storage capabilities as needed.

Benefits of Cantilever Racking

- Maximized Storage Space: Since cantilever racking allows for vertical storage, it helps in effectively utilizing warehouse height without overcrowding the floors.

- Easy Accessibility: The open design of cantilever racks provides clear visibility and easy access to items, reducing the time spent locating and retrieving products.

- Customization: Cantilever racks can be customized to fit different dimensions and capacities, making them versatile for a variety of industries, from construction and manufacturing to retail and distribution.

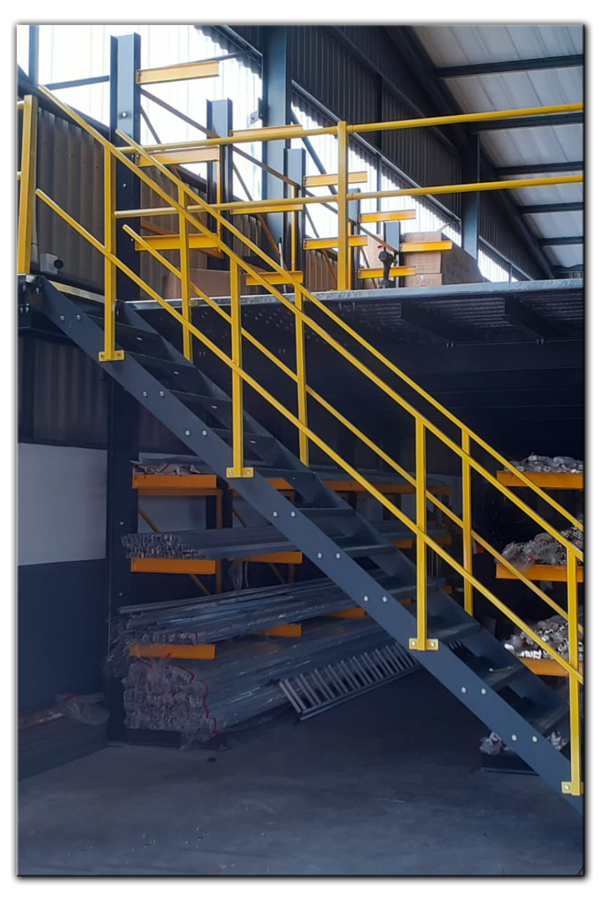

- Increased Safety: The stable design minimizes the risk of items tipping over, while also facilitating the organization of products to reduce accidents and improve workplace safety.

- Cost-Effective: By optimizing storage space, businesses can store more goods without needing to increase their warehouse footprint, leading to significant savings in operational costs.

Common Uses of Cantilever Racking in Warehouses

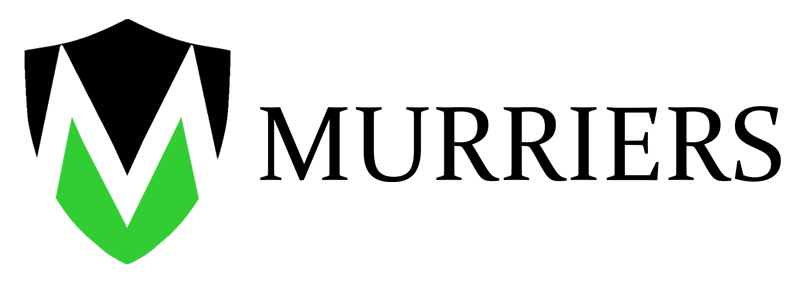

1. Lumber and Building Materials

One of the primary applications of cantilever racking is in the lumber industry. Long and heavy pieces of wood can be stored efficiently, allowing easy access for loading and unloading. This helps suppliers manage inventory and fulfill orders faster.

2. Steel and Metal Pipe Storage

Manufacturing industries often deal with bulky and heavy materials like steel and metal pipes. Cantilever racking provides robust support for these materials, allowing them to be stored in a way that optimizes space and ensures safety during handling.

3. Furniture and Large Goods

Retailers of furniture and other large consumer goods benefit from cantilever racks' ability to display items in an organized manner. This allows for efficient stock management and helps consumers easily browse products.

4. Automotive Parts

In automotive warehouses, where space can often be at a premium, cantilever racks are used to store various lengths of automotive parts, including exhausts, seals, and panels, ensuring that everything is easy to find and retrieve.

5. Industrial Equipment

For warehouses handling industrial equipment, cantilever racking allows for bulk storage of larger items without compromising safety or accessibility.

Comments